Flex Weave Bamboo

Every crop harvested and engineered contributes to our global well-being.

EcoMatPro® and KodeK® eco-friendly and renewably resourced products are manufactured using our proprietary Flex Weave process to create ultra-high-density, strand-woven bamboo.

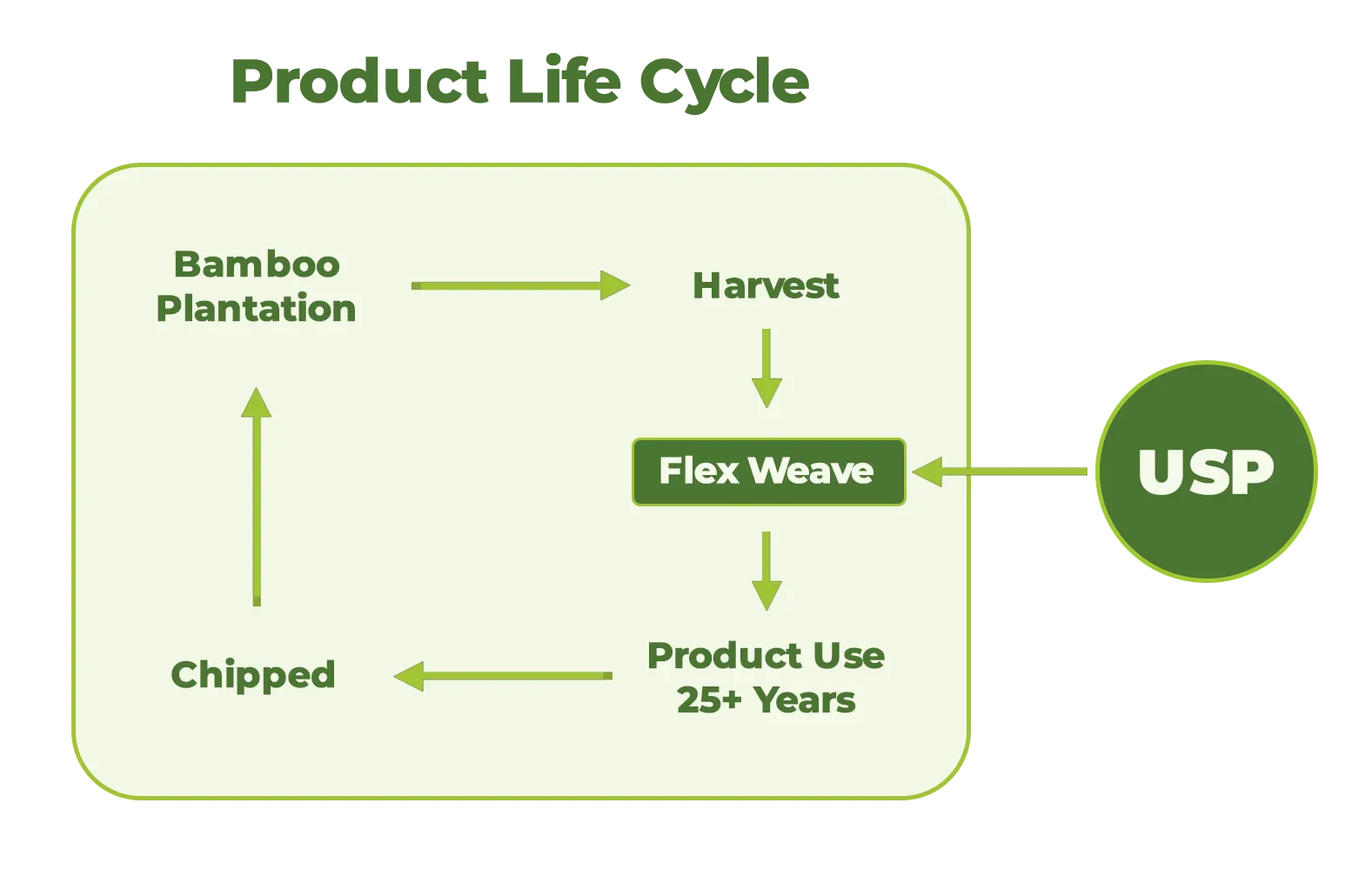

Engineered as a replacement for timber, concrete, WPC, PVC, and other synthetic polymers that contribute to long-term waste or have a high Co2e impact. Our products are fully sustainable throughout their life cycle. Our products have a complete cycle, Flex Weave can be chipped at end-of-life and returned to the earth as bio-char compost.

Flex Weave Process

EcoMatPro® and KodeK® eco-friendly and renewably resourced products are manufactured using our proprietary Flex Weave process.

Flex Weave, our USP, creates ultra-high-density, strand woven bamboo which gives all of our products the same inherent advantages – including Class 1 Durability, UC4 Classification, and Fire Class A Rating. Flex Weave products are fully sustainable throughout their life cycle and can be chipped at end-of-life and returned to the earth as bio-char compost.

How Flex Weave Bamboo

Can Boost Your Performance